Share

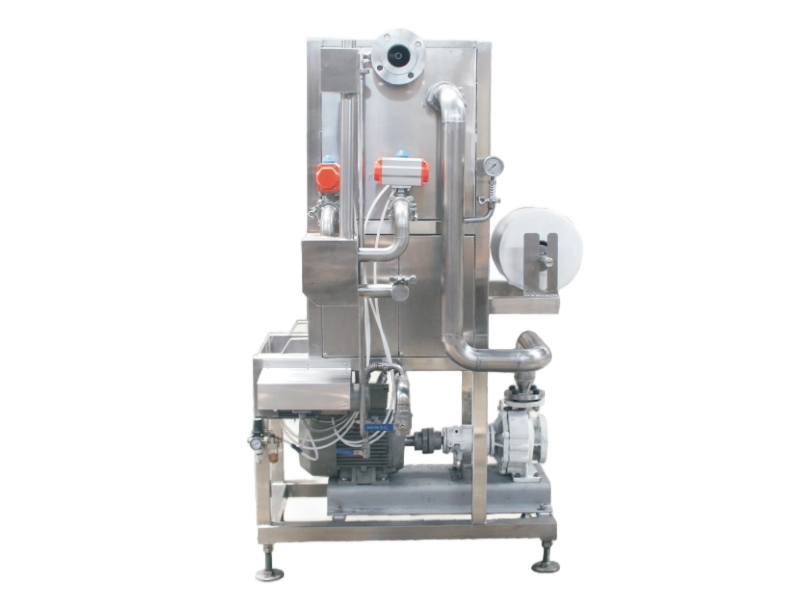

LH 250-A frying oil filter

Product model:

Still thinking about it? If you want to get a sample first,Please contact us!

Current Product Classification

- Product Description

-

LH 250-A frying oil filter is equipped with an automatic alarm safety system. In case of filter layer blockage or oil outlet pipe blockage, it will automatically issue a warning and stop immediately.

It is suitable for continuous filtration of the production line with oil storage capacity of more than 1000kg in the frying tank, and the frying filtration is carried out simultaneously. This machine is equipped with FS250-A filter paper.

Technical parameters

Model LH 250-A (5-segment) LH 250-A (Seven-segment) Oil filtration rate (l/min) (based on new oil 170°C) 200 200 Oil capacity of filter chamber (liter) 194 194 Form of work Fixed Fixed Filtration area (m2) 3.18 4.4 Inlet and Outlet Pipe Diameter (inches) Imports 3 3 Export 3 3 Dosage of filter paper (sheet/time) 5 7 Dosage of filter aid (kg/time) 3 4.5 Total power (kW) 5.5 5.5 Power 380V,50Hz 380V,50Hz Total Weight (kg) 450 500 External dimensions (length x width x height) mm 1250X1200X1400 1250X1200X1400 The LH 250-A frying oil filter is designed to handle large-scale frying operations, suitable for production lines with a frying tank oil storage capacity of over 1000kg. Its ability to filter oil continuously while frying is a significant advantage, ensuring consistent oil quality and extending the life of the oil, which is crucial for maintaining flavor and reducing costs in high-volume settings.

This filter model uses the FS250-A filter paper, specifically engineered to accommodate the high throughput and demanding conditions of the LH 250-A. The filter paper is effective in capturing fine particles and impurities, ensuring that the oil remains clean and clear throughout the frying process. This contributes to superior food quality and a reduction in oil waste.

Equipped with an automatic alarm safety system, the LH 250-A enhances operational safety by detecting and alerting operators to any blockages in the filter layer or oil outlet pipe. This immediate response prevents potential equipment damage and ensures that the filtration process does not compromise food safety or quality.

The LH 250-A's integration into production lines is streamlined thanks to its robust design and automated features, making it an indispensable tool for businesses that require reliable and efficient oil filtration. Its continuous operation capability allows for non-stop production, which is essential for meeting high demand without sacrificing the quality or safety of the food being fried.

Consultation

We will contact you within one working day. Please pay attention to your email.