ABOUT US

Our goal is to improve the quality of attention to every customer

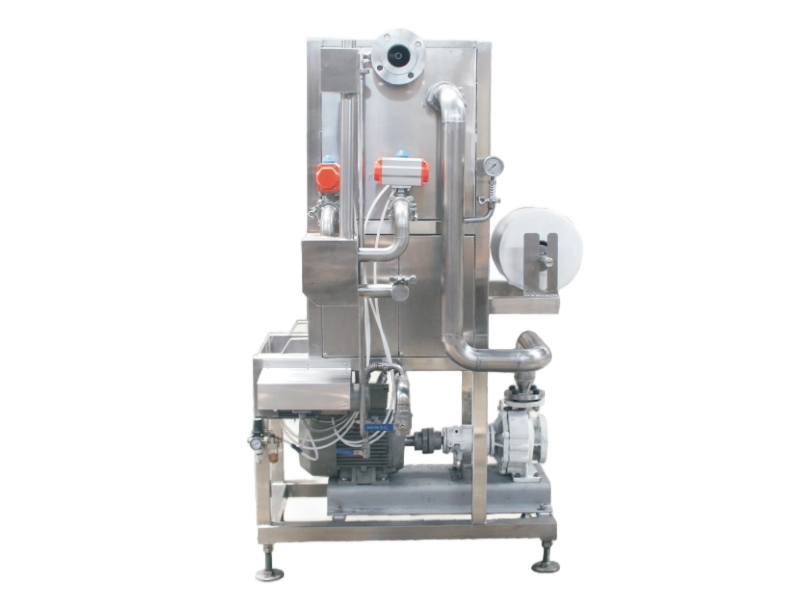

Cangzhou Yaoda Machinery Equipment Co., Ltd. is a professional manufacturer of oil filtration equipment in China. The company is located in Hejian Economic Development Zone, Hebei Province. The company covers an area of 30000 square meters, has professional standardized operations, and has a workshop of 18000 square meters. The company introduced advanced welding, cutting, CNC processing equipment at home and abroad, making the product quality improved. The Dream brand filter specializes in filtering visible impurities, de-gumming, de-waxing and more. Providing efficient solutions for edible oil production companies.

Company covers an area

COOPERATION CUSTOMERS

Sales country and region

Company advantage

Science and technology to enhance efficiency, quality achievements brand; The goal of the enterprise is to pursue.

We continue to carry out technological innovation, and strive to establish their own credibility competitiveness, to provide customers with better products. The company introduced advanced welding, cutting, CNC processing equipment at home and abroad, making the product quality improved. its filter sea brand oil filter focused on the food industry frying oil solid-liquid separation filter.

We can produce grease filter according to customer's need, welcome customer OEM order cooperation.

We attach great importance to quality control from the very beginning, from very small things (even a small screw, we will choose the best quality).

News dynamics

The company continues to develop, process and technology continue to improve, product quality, market competitiveness continues to improve.

When it comes to selecting the best edible oil filter machine for your industrial needs, there are several factors to consider. Here are some key points to keep in mind: 1. Filtration Efficiency: The efficiency of an edible oil filter machine is crucial for ensuring the quality of the end product. Look for machines that offer high filtration efficiency to remove impurities effectively. 2. Capacity

**Introduction: The Significance of Fryer Oil Filtration Machines** In the competitive landscape of the industrial equipment and components industry, businesses are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. One critical component that plays a key role in achieving these objectives is OEM fryer oil filtration machines. These machines are specifically

Quality fryer oil filtration machines play a crucial role in ensuring the efficiency and longevity of industrial fryers and other equipment. Proper filtration not only extends the life of the oil but also improves the quality and taste of fried foods. Here are some top tips for selecting and maintaining quality fryer oil filtration machines: 1. Filter Capacity: When choosing a fryer oil filtration

Need to know moreProductsTypes and parameters?

For inquiries about our products, please leave your contact number and we will contact you within 24 hours.